These circuit breakers are used to connect or disconnect power supply units to furnaces. In many cases it is needed to disconnect furnace from power supplies. For example when the refractory lining of the furnaces needs to be replaced, the corresponding furnace disconnects from the power supply and the other furnace connects to it. Another example happens in Hold and melt arrangement. In this arrangement there is a main power supply and another auxiliary power supply which has lower power capacity. During the melting process in one furnace which is connected to main power supply, the melt in the other furnace can be kept on holding duty by auxiliary power supply. In this case when the main power supply is connected to one furnace and keeps melting the scrap until it reaches it’s nominal capacity, circuit breaker has to disconnect the main power supply from that furnace and connect to another furnace to apply it full power. At the same time, auxiliary power supply should be connected to first furnace by another circuit breaker to hold motel metal in suitable temperature until discharging is completed.

These circuit breakers are designed precisely to ensure efficiency , persistency and durability in different working conditions. Damavand induction furnace company’s engineers have optimized different parts of these circuit breakers to maximize lifetime and performance.

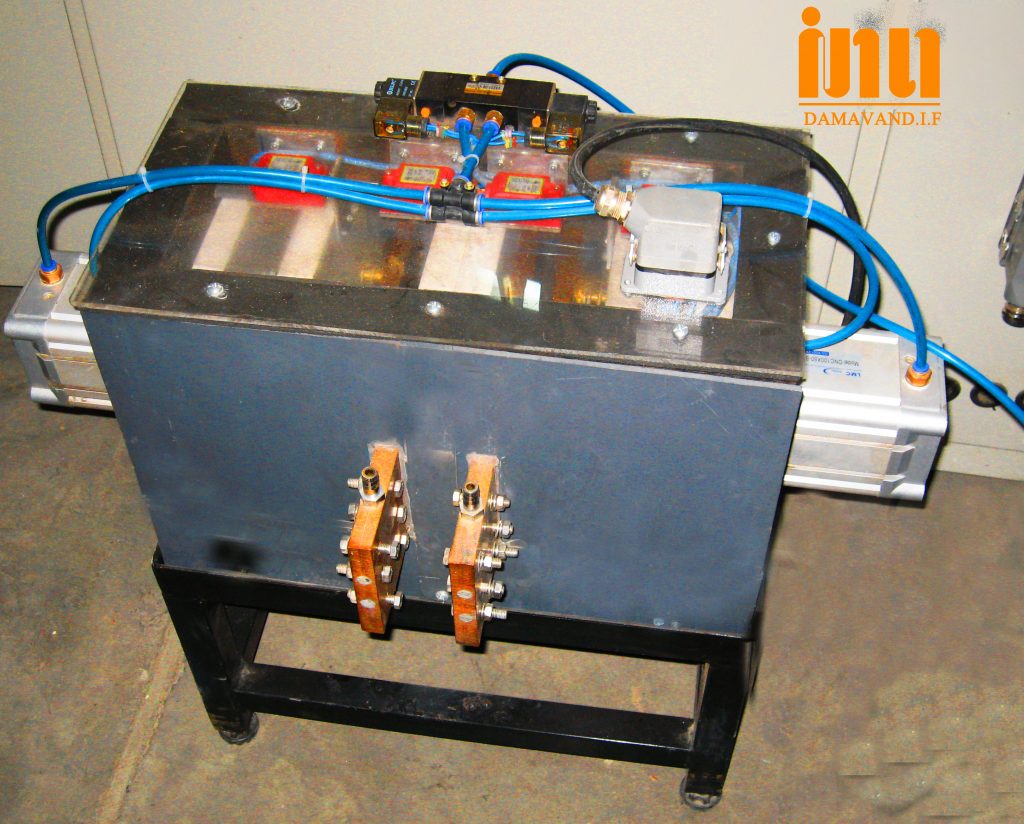

Pneumatic jacks that are control by the central control unit, move the connecting bar of the circuit breaker. Operator can close or open each circuit breaker by HMI ( Human machine interface)