Power supplies apply electrical power to induction coil. Electrical power from the mains converts to a high frequency sinusoidal current in the heating coil which generates an alternating magnetic field in the coil. This electromagnetic field induces a corresponding electrical current in each inductor in the vicinity of the coil. Power supplies made by Damavand induction furnace company have versatile range of power and frequency. From 300 Hz to 50 KHz and from 5 kilo watts to 5 Mega watts. This power supplies are working in heavy duty state in several foundries around the country. Precise and engineering design, high electrical efficiency beside modern technology has made these power supplies well known in Iran, and first choice for those customers who are searching for induction furnaces which have high quality ,reliability and standards.

These power supplies work on the basis of series resonant circuit which has the following advantages:

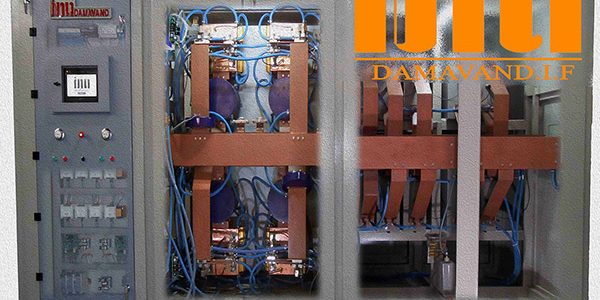

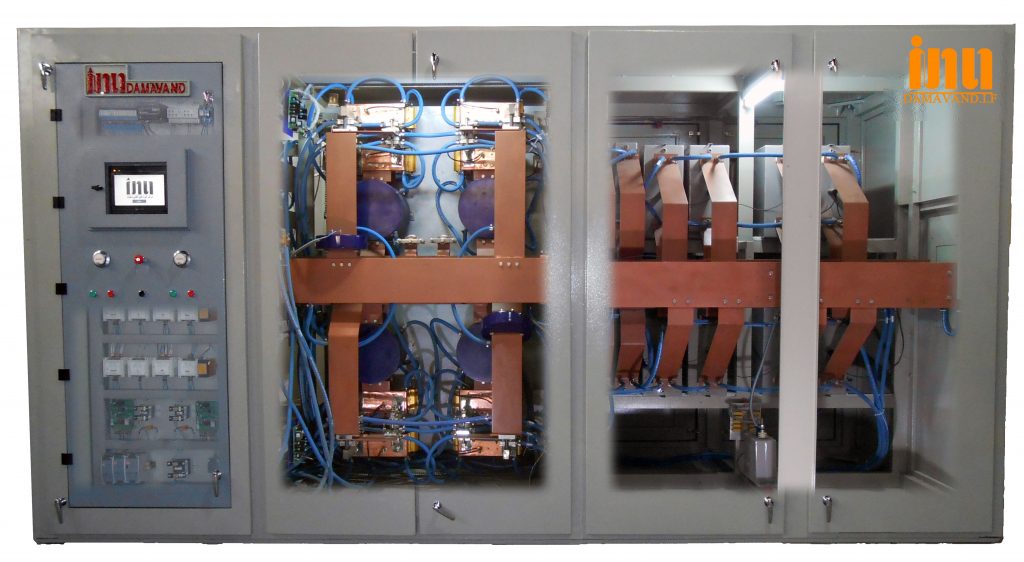

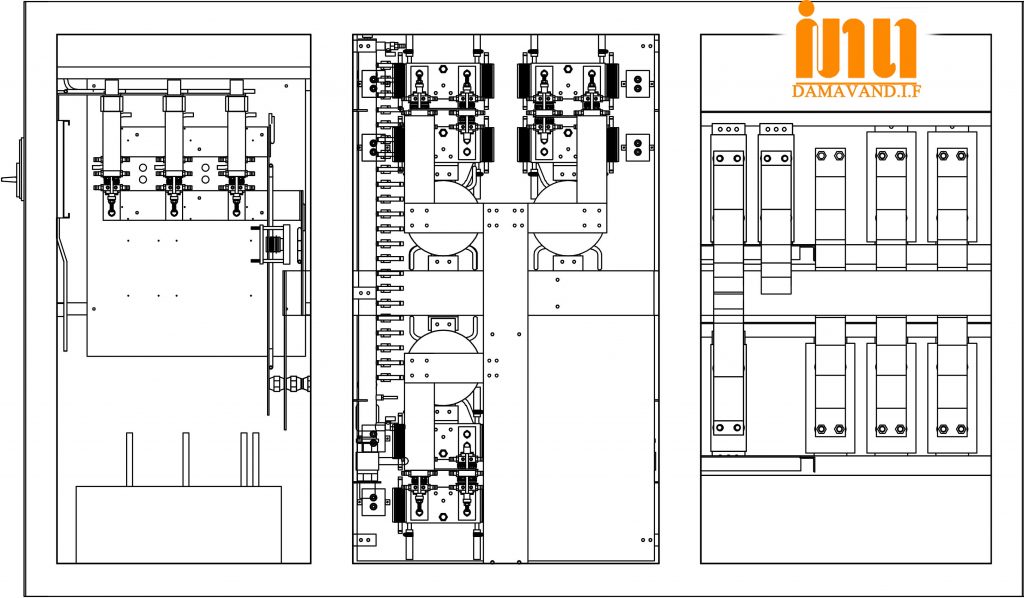

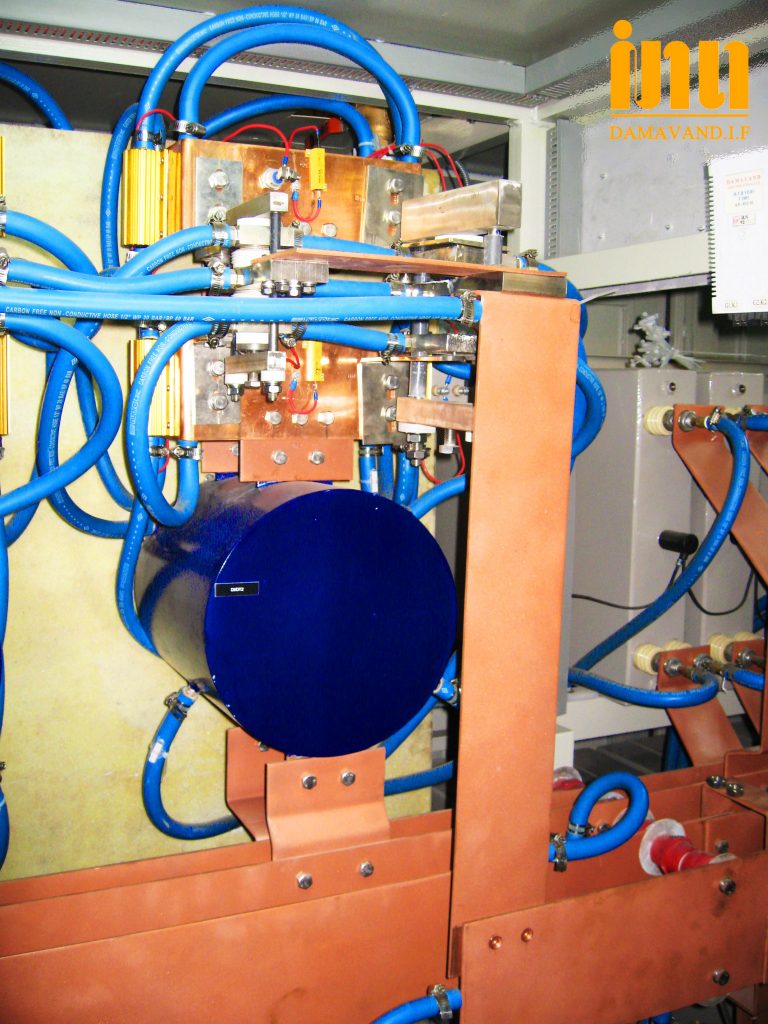

- All parts of the power supply are placed in a single cabin which guarantees good immunity, lower needed space and easy installation and maintenance.

- Due to natural characteristics of series resonant inverter, it is possible to apply full power to load from the beginning of melting process unlike parallel resonant inverter in which at the begging of melting, applied power should be limited so less throughput would be reached.

- There is no reactive power consumption in series resonant inverters unlike parallel resonant inverters in which power reactive power consumption increases when system is running on low powers. Reactive power consumption imposes additional costs to user. Moreover power controlling method in parallel resonant inverters inserts current harmonics into power system and disturbs different pieces of electrical equipment on the system.

Other features and advantages of our power supplies are as follows:

- Control systems designed by Damavand induction furnace ‘s company, detects faults of the system immediately and in the case of short circuit or any other fault, protects the system from any damage and guarantees it’s proper performance.

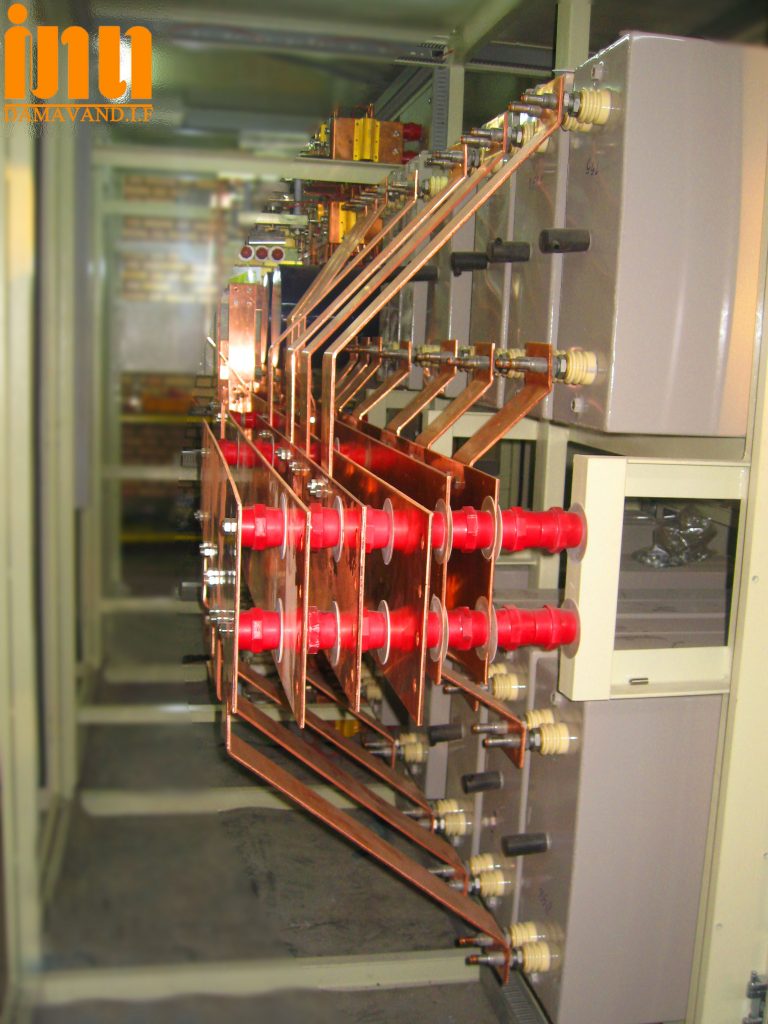

- Thyristors used in power circuits, are approximately working on half of their nominal ratings. This causes less current stress, lower working temperature and increases their lifetime.

- Power of the system is adjusted by the operator and in the case of different types of loads output power is controlled so that the set point power indicated by the operator is reached. This increases repeatability of the melting process.

- Power electronic devices used in power supply, are reliable and manufactured by well known companies, which guarantee appropriate performance in the long term and reduces maintenance costs.

- Automatic earth leak detection system is designed to control the thickness of refractory linings of the furnace. Electromagnetic field in the melting coil, causes stirring which in turn causes corrosion in the internal linings of furnace and depending on the type of refractory layer, it’s thickness decreases. A thin layer of refractory lining increases chance of leaking molten metal to the heating coil in which water is circulating .This may cause an explosion. There should be a control system to monitor the thickness of the refractory lining thickness in order to ensure security.

- Central control unit shows necessary data of the system to the operator. These data consists of water temperature and pressure, power, status of furnaces in different working conditions, frequency and earth leak current. These data are valuable for the operator to have a good image from the overall system and take appropriate action in the case of errors .

- Proper layout of elements in the power supply’s cabin, offers good access when maintenance is needed. More over a full operation manual consisting system tutorial and common troubleshooting notes is prepared for the operator which facilitates after sales services and corresponding maintenance.